|

|

Aircraft Type |

Carrier-borne fighter |

|

Manufacturer |

Vought-Sikorsky Aircraft / Chance Vought |

|

Engine |

Radial 18-cylinder, air-cooled, 2,804 cid |

|

Horsepower |

2,100 hp (1,566 kW) at 2,800 rpm

|

|

Weight |

9,205 lb (empty)

12,420 lb

(gross) |

|

Max Speed |

446 mph (387 kn, 717 km/h) |

|

Configuration |

Single

seat (pilot) |

|

|

| |

|

The Vought-Sikorsky F4U Corsair was an

American fighter aircraft that saw service primarily in

World War II and the Korean War. Demand for the aircraft

soon overwhelmed Vought's manufacturing capability,

resulting in production by Goodyear and Brewster.

Goodyear-built Corsairs were designated FG

and Brewster-built aircraft F3A. From the

first prototype delivery to the U.S. Navy in 1940, to final

delivery in 1953 to the French, 12,571 F4U Corsairs were

manufactured by Vought, in 16 separate models, in the

longest production run of any piston-engined fighter in U.S.

history (1942–53).

The Chance-Vought F4U Corsair first flew on May 29, 1940.

The fighter was designed as a carrier-based aircraft.

However its difficult carrier landing performance rendered

the Corsair unsuitable for Navy use until the carrier

landing issues were overcome when used by the British Fleet

Air Arm. The Corsair thus came to and retained prominence in

its area of greatest deployment: land based use by the U.S.

Marines. The role of the dominant U.S. carrier based fighter

in the second part of the war was thus filled by the Grumman

F6F Hellcat, powered by the same Double Wasp engine first

flown on the Corsair's first prototype in 1940. The Corsair

served to a lesser degree in the U.S. Navy. As well as the

U.S. and British use the Corsair was also used by the Royal

New Zealand Air Force, the French Navy Aéronavale and other,

smaller, air forces until the 1960s. Some Japanese pilots

regarded the F4U Corsair as the most formidable American fighter of World

War II, and the U.S. Navy.

After the carrier landing issues had been tackled it

quickly became the most capable carrier-based fighter-bomber

of World War II. The Corsair served almost exclusively as a

fighter-bomber throughout the Korean War and during the

French colonial wars in Indochina and Algeria.

|

Company History

|

|

Over the decades, the

Vought name has traversed an interesting, yet convoluted

corporate maze. The industry dominance of its large parent

companies, have

invoked anti-trust laws more than once, and it has seen a

myriad of corporate buyouts. Vought now belongs to the

Triumph Group, an aerospace component manufacturer. It

operates as Triumph Aerostructures - Vought Aircraft

Division, making aft fuselage sections for the Boeing 787

Dreamliner. |

Chance Vought years 1917–1928

The Lewis and Vought Corporation was founded in 1917 and

was soon succeeded by the Chance Vought Corporation in 1922

when Birdseye Lewis retired. A former chief engineer of the

Wright Company, Chance M. Vought founded the company to take

advantage of the growing field of military and civilian

aviation after World War I. Operations began in Astoria, New

York and in 1919 were moved to Long Island City, New York.

Vought died from septicemia in 1930, but in that short

time period succeeded in producing a variety of fighters,

trainers, flying boats, and surveillance aircraft for the

United States Navy and the United States Army Air Service.

Vought made history in 1922 when their Vought VE-7 trainer

made the first takeoff from the deck of the USS Langley, the

first American aircraft carrier. Following this success came

the VE-11 naval fighter and the Vought O2U Corsair, the

first of the Corsair aircraft.

In 1928, the company was acquired by United Aircraft and

Transport Corporation, but stayed its own separate division

among the likes of Pratt & Whitney and Boeing.

1930s–1960

Despite the Great Depression, Vought continued to design

and manufacture aircraft at a growing pace. Soon after

Chance Vought's death in 1930, the company moved its

operations to East Hartford, Connecticut. Under the Air Mail

Act of 1934, United Aircraft and Transportation Corp. was

forced by law to divide its businesses, resulting in Boeing

Aircraft, United Airlines, and the United Aircraft Corp, of

which Vought was a part. In 1939 United Aircraft moved

Vought to Stratford, Connecticut where their Sikorsky

division was located and renamed the merged divisions

Vought-Sikorsky Aircraft.

Chief Engineer Rex Beisel began in 1938 to develop the

XF4U, recognized by its distinctive inverted gull wings.

After its first flight in 1940, thousands of F4U Corsairs

were produced for the Navy and Marines in World War II. By

the end of its production in 1952, Vought, Goodyear, and

Brewster had all produced the Corsair fighters. Vought was

reestablished as a separate division in United Aircraft in

1942.

|

|

|

|

Vought-Sikorsky Aircraft

Division of United

Aircraft Corporation

1939-1943

Stratford, Connecticut

|

|

Chance Vought Aircraft

Division

of United

Aircraft Corporation 1943-1954

(Move to

Dallas, Texas in 1948) |

|

|

|

Timeline

|

| 1917 |

|

Lewis and Vought Corporation is

founded by Birdseye B. Lewis and Chauncey "Chance"

Milton Vought in

Astoria, NY. |

| 1918 |

|

Lewis and Vought Corp. moved to Long Island

City, NY. |

| 1922 |

|

Lewis and Vought was reorganized as the Chance

Vought Corporation when Lewis retired. |

| 1929 |

|

Renamed Chance Vought Aircraft, the company

moved to East Hartford, Connecticut when acquired by

a newly formed holding company, United Aircraft and

Transport Corporation (UATC). Vought joined other

subsidiaries acquired by UATC that included Pratt &

Whitney engines, Hamilton Standard propellers,

Sikorsky Aircraft, and Boeing Airplane and

Transport. |

| 1930 |

|

Chance M. Vought dies from septicemia at age 40.

F. B. Rentschler (Chairman of UATC) is elected

President of the subsidiary. |

| 1934 |

|

Under the Air Mail Act of 1934, and new

anti-trust laws, UATC is forced to dissolve on

September 26, 1934. Chance Vought Aircraft becomes

part of newly formed United Aircraft Manufacturing

Company (UAMC). |

| 1935 |

|

By June, all but Boeing formed the UAMC, part of

the new United Aircraft Corporation (UAC). UAMC

subsidiaries included Chance Vought Corp., Hamilton

Standard Propeller Co., Sikorsky Aircraft Corp., The

Pratt & Whitney Aircraft Co., United Aircraft

Exports Corp., and The United Airports of

Connecticut, Incorporated. UATC's airline interests

went on to become United Air Lines (UAL). A separate

United Aircraft Exports Corporation (UAEC) was

organized. All in turn were subsidiaries of the

United Aircraft Corporation (UAC). |

| 1937 |

|

R. W. Clark became general manager of Chance

Vought Aircraft and Sikorsky Aircraft divisions. |

| 1939 |

|

Vought and Sikorsky merged and becomes Vought-Sikorsky Aircraft, and became a single

division under UAC. Vought was moved from East

Hartford to Stratford,

CT, where the larger Sikorsky plant was located. |

| 1940 |

|

C. J. McCarthy was appointed general manager of

Vought-Sikorsky Division. The F4U

Corsair first flew on May 29, 1940. |

| 1943 |

|

Chance Vought and Sikorsky

divisions were reconstituted, with Vought assuming

its former title, and Sikorsky moving to a new site

in Bridgeport to concentrate on helicopter

development and production. |

| 1948 |

|

Chance Vought Aircraft moves to Dallas, Texas.

Frederick O. Detweiler is named general manager. |

| 1954 |

|

Vought separates from the UAC and becomes an

independent corporation again on July 1, 1954.

Detweiler becomes president of Chance Vought

Aircraft, Incorporated. The company was spun off

(first as a subsidiary in January 1954) owing to

concerns that it might gain unfair advantage from

Pratt & Whitney's dealings with other manufacturers. |

| 1960 |

|

The company became Chance Vought Corporation on

December 31, 1960, with its aircraft section called

the Aeronautics Division. |

| 1961 |

|

Vought merged with Ling-Temco Electronics

and formed Ling-Temco Electronics, Inc., following Vought's failed antitrust suit against

Ling. Paul Thayer, a former test pilot, replaced F. O. Detweiler as

president of Vought. |

| 1963 |

|

The "Chance Vought" name survived until a

reorganization of Ling-Temco-Vought (LTV) on October

20, 1963. |

| 1965 |

|

Vought Aeronautics formed as a division of LTV

Aerospace Corporation, a subsidiary of LTV

Incorporated. Vought operations

comprised

the bulk of the division. |

| 1969 |

|

The company name was changed from Vought

Aeronautics Division to Vought Aeronautics

Company, a division of LTV Aerospace

Corporation. |

| 1971 |

|

Ling-Temco-Vought was renamed LTV Corporation.

It had three divisions, LTV Aerosystems,

LTV Electrosystems, and LTV Ling-Altec. By this

time, LTV Aerosystems was comprised of Vought Aeronautics Company, a few other

units, and Vought Helicopters, Inc. |

| 1972 |

|

The Vought units were reorganized as the Vought

Systems Division of LTV Aerospace. The aircraft

producing unit was named the Vought

Aeronautics Division. |

| 1973 |

|

Vought Aeronautics Davison name was changed to

Vought Systems Division to reflect

its desire to diversify. |

| 1976 |

|

All of LTV Aerospace renamed

Vought Corporation on January 1,

1976. The parent company LTV Corporation had become

a $4 billion diversified conglomerate. |

| 1983 |

|

Vought Corporation was again split along

aeronautic and missile lines under LTV

Aerospace and Defense Company. |

| 1992 |

|

Vought and LTV split. Vought was purchased by

Northrop and Carlyle Group, each

owning about 50%. |

| 1994 |

|

Northrop Grumman, the successor

to Northrop and Grumman, bought out Carlyle Group's

share of Vought for $130 million. |

| 2000 |

|

Carlyle Group purchased the

entire company from Northrop Grumman and established

Vought Aircraft Industries, Inc. Its function was primarily as an aero-structures

subcontractor with heavy involvement in the Boeing

747 and 787 as wells as supplying parts for various

military aircraft. |

| 2003 |

|

The Aerostructures Corp., owned

by the Carlyle Group and based in Nashville, merged

with Vought. |

| 2009 |

|

Boeing acquired the Vought

Aircraft Industries manufacturing facility, in North

Charleston, SC, for $580 million. |

| 2010 |

|

The Carlyle Group sold Vought to the Triumph

Group, an aerospace component manufacturer. The

Vought acquisitions now operate as Triumph

Aerostructures - Vought Aircraft Division. |

|

|

|

|

|

|

|

Specifications F4U-4 Corsair

Bureau of Aeronautics Navy Department (Mar 1946)

| General Characteristics (Loading condition 1 combat) |

| Crew: |

|

One pilot |

| Length: |

|

33 ft 8.25 in (10.2 m) |

| Wingspan: |

|

40 ft 11.75 in (12.5 m) |

| WS Folded: |

|

17 ft 0.5 in (5.2 m) |

| Height 3-Pt.: |

|

14 ft 9.5 in (4.5 m) |

| Height Folded: |

|

16 ft 4.5 in (5.0 m) |

| Length Level: |

|

|

| Wing area: |

|

314 ft² (29.2 m²) |

| Empty weight: |

|

9,205 lb (4,174 kg) |

| Gross weight: |

|

12,420 lb (5,633 kg) |

| Powerplant: |

|

1 × Pratt Whitney R-2800-18W radial engine, 2,100 hp (1,566 kW) |

| Propeller: |

|

4-blade Hamilton Standard, 13 ft 2 in (4 m) |

| |

|

|

| Performance |

| Top speed: |

|

446 mph (387 kn, 717 km/h) |

| Stall speed (GW) |

|

89.4 mph

(77 kn, 143 km/h) |

| Range: |

|

897 mi (602 nmi (1,115 km)) |

| Rate of climb: |

|

3,870 ft/min (19.7 m/s) |

| Service ceiling: |

|

41,500 ft (12,649 m) |

| Time to altitude: |

|

2.9 min to 10,000 ft (3,048 m) |

| |

|

|

| Armament |

| Guns: |

|

6 × 0.50 in (12.7 mm) AN/M2 Browning machine guns, 400 rounds per gun, or4 × 0.79 in (20 mm) M2 cannon |

| Rockets: |

|

8 × 5 in (12.7 cm) high velocity aircraft rockets and/or |

| Bombs: |

|

4,000 pounds (1,800 kg) |

|

| |

|

| Aircraft silhouette |

| |

| |

|

Vought-Sikorsky Aircraft

United

Aircraft Corporation

Stratford, Connecticut

1939-1943 |

| |

|

|

|

|

|

| |

| |

|

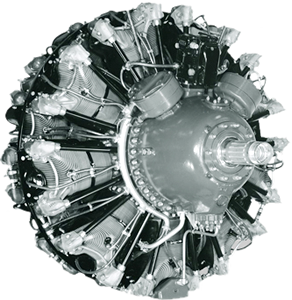

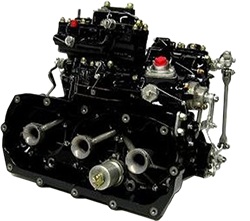

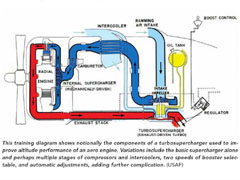

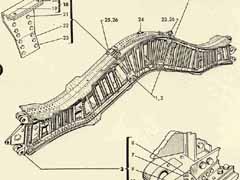

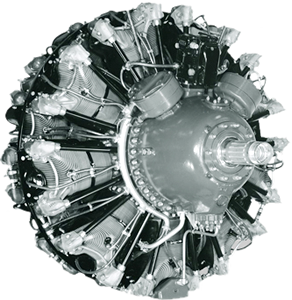

Engine Specifications

Pratt & Whitney R-2800-18W Double Wasp "C"

Series

| General specs |

|

|

| Type: |

|

18-cylinder air-cooled twin-row supercharged radial piston engine with water injection |

| Bore: |

|

5.750 in (146.05 mm) |

| Stroke: |

|

6.000 in (152.4 mm) |

| Displacement: |

|

2,804 in³ (46 L) |

| Diameter: |

|

52.8 in (1,342 mm) |

| Dry weight: |

|

2,360 lb (1,073 kg) |

| |

|

|

| Components |

|

|

| Valvetrain: |

|

Two overhead valves per cylinder |

| Supercharger: |

|

Two-stage, two-speed, centrifugal type supercharger |

| Reduction gear: |

|

2:1 |

| Fuel system: |

|

One Bendix-Stromberg PT-13G2-10, updraft, pressure carburetor, 3-venturi |

| Fuel type: |

|

100/130 octane gasoline |

| Cooling system: |

|

Air-cooled |

| |

|

|

| Performance |

|

|

| Power output: |

|

2,100 hp (1,566 kW) at 2,800 rpm for takeoff, up to 2,380 hp (1,775 kW) WEP |

| Specific power: |

|

0.75 hp/in³ (34.0 kW/L) |

| Compression ratio: |

|

6.75:1 |

| Power/weight ratio: |

|

0.89 hp/lb (1.46 kW/kg) |

| Engine was

the first series production variant of the

"C" Series, which was a complete

redesign of the R-2800. Some of the main

changes were forged, rather than cast

cylinders, allowing an increased

compression ratio (from 6.65:1 to

6.75:1), a redesigned crankshaft, a

single piece, rather than split

crankcase center section, and a two

section nose casing, incorporating

hydraulically operated torque-monitoring

equipment and an automatic, vacuum

operated spark-advance unit. The

supercharger used fluid coupling for the

second stage. Updraft Bendix-Stromberg

PT-13G2-10 carburetor. Production =

3,257 (P&W). |

|

|

Pratt & Whitney |

|

R-2800-18W "Double Wasp" |

|

|

1939-1960 |

|

The 18-cylinder twin-row air-cooled

radial piston engine was 2,804 cubic

inches, supercharged, and water

injected. Production of the (P&W) R-2800

"C" Series totaled 3,257. |

|

|

|

|

Bendix-Stromberg

PT-13G1 |

|

Pressure (injection),

3-venturi carburetor |

|

|

| |

|

|

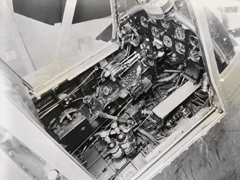

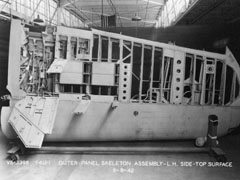

Photos

|

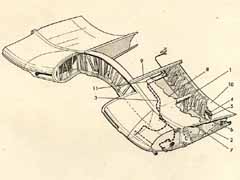

F4U Corsair Design

|

|

|

Corsair XF4U-1 Prototype

|

|

|

| |

The NACA Full-Scale Wind Tunnel

|

National Advisory Committee for Aeronautics

Langley Memorial Aeronautical Laboratory

in Hampton, Virginia |

| In 1931, work was completed on what was then the world's

largest wind tunnel with a 30-ft by 60-ft test section, known as the Langley

Full Scale Tunnel. Designed by Langley staff, the tunnel could study entire

full-sized aircraft of the time and was instrumental in doing drag clean-up

studies for nearly every U.S. Fighter aircraft design in the World War II era.

The Full Scale Tunnel went on to test the Mercury space capsule, the lunar

lander test vehicle, F-16, concepts for super sonic transports, and the space

shuttle. This tunnel was also designated a National Historic Landmark, but has

since been declared obsolete and demolished. |

|

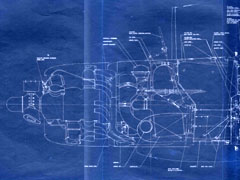

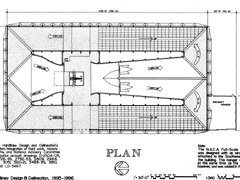

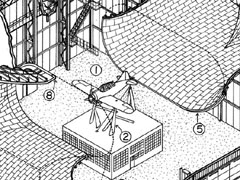

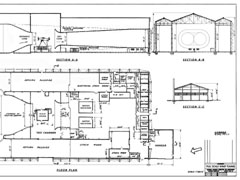

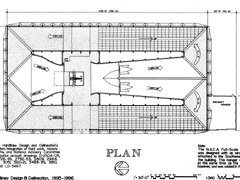

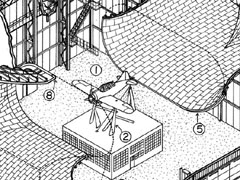

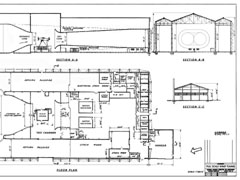

Drawings of Full-Scale Wind Tunnel - Building Number 643

|

|

NASA-Langley Research Center Recording Project. Historic

American Engineering Record. National Park Service. U.S.

Dept. of the Interior. (1995-96). |

|

|

|

|

Site Plan and Building Plan |

Cutaway Isometric Detail |

Sections and Floor Plan |

|

Photos of F4U "Corsair" in

Full-Scale Tunnel 1942-43

|

|

|

Vought-Sikorsky Aircraft

Final Assembly Line in Stratford, Connecticut |

|

|

U.S. Navy Operational Training and Combat Use

|

|

|

Other Images

|

|

|

|

|

|

References

|

|

1. |

Celtic Cowboy Company.

(2013). Aeroplanes Vought.

Retrieved from http://celticowboy.com/index.htm |

|

2. |

Triumph Aerostructures

- Vought Aircraft Division. (2014). Vought

Aircraft Industries, Inc. History. Retrieved

from

http://www.fundinguniverse.com/company-histories/vought-aircraft-industries-inc-history/ |

|

3. |

U.S. Centennial of

Flight Commission. (2013). Vought Aircraft.

Retrieved from http://www.centennialofflight.net/essay/Aerospace/Vought/Aero23.htm |

|

| Photos |

|

4. |

Library of Congress. (2015). Prints &

Photographs Online Catalog. Retrieved from

http://www.loc.gov/pictures/ |

|

5. |

NASA Cultural Resources. (2011).

Test 142 - Vought-Sikorsky F4U-1.

Retrieved from

http://crgis.ndc.nasa.gov/historic/643_Test_142_-_Vought-Sikorsky_F4U-1 |

|

6. |

U.S. Centennial of

Flight Commission. (2013). Vought Aircraft.

Retrieved from http://www.centennialofflight.net/essay/Aerospace/Vought/Aero23.htm |

|

|

|